Stabilizers

The stabilizers are basic compounds which in combination with lubricants, produce stabilizing systems that are remarkably effective for the processing of PVC. Stabilizers provide give the final product with:

good thermal stability

good stability to light

good electrical properties

They are mainly used in pipes, fittings, construction profiles, window frames, panels, floor coverings, cables, …

Ecology

Stabilizers are applied exclusively to long-life products, so that PVC is found in household waste only in small quantities.

Compounds applied to the processing of PVC, possess a poor solubility are solidly fixed to the PVC matrix and are hardly volatile at all.

Laboratory research work has shown that the PVC particles found in the debris do not exhibit stabilizer leakage phenomena of stabilisers and therefore, do not produce water pollution filtration.

PVC Recycling

- PVC is a 100% recyclable material. Recycled PVC is used to manufacture co-extruded pipe, electric pipes, eater, gutters and downspouts for water drainage, fittings, tiles,…

- The paper, plastics and cardboard collected separately are used to make packaging derived fuel or for recycling by grinding.

- Household waste is classified and used for waste derived fuel, in the thermal plant or industrial burner.

- Hot water heating in homes, schools and local industry.

- Steam for industry.

- Electricity for the national grid

- Plastic bottles, etc., are recycled. PVC is identified and separated. Once separatedit is crushed into flakes, washed and removed the impurities are removed (caps, labels, glue …). Finally the flakes are reduced to a fine powder, ready to be reused.

Thermal recovery

One of the advantages of PVC is its low carbon content, this way the burning releases less carbon dioxide (CO2) than coal.

The PVC plastic together with other plastics makes the fuel consumption in municipal waste incineration unnecessary.

Waste heat recovery has two advantages: the energy recovered as steam or electricity and reduces the waste volume.

Ecobalance

PVC comes from salt (57%) and oil (43%). Oil dependency is therefore less than that of other plastics.

The manufacture of all plastics represents 4% of world oil consumption, of which only 0.5% is PVC.

Since salt is an abundant raw material and oil consumption to manufacture PVC is very moderate, PVC has a great advantage over other polymers and compared to other materials it contributes to a better utilization of natural resources.

Studies on the impact of PVC on the environment, show a favorable ecological balance to this plastic material, when it is compared to other traditional materials and with other plastics.

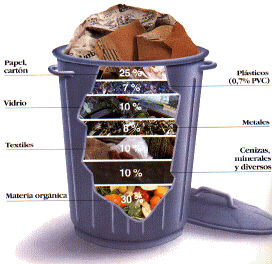

If the ratio of plastics may seem significant in volume, weight only accounts for 0.7% of total household waste collected every year in Europe.

PVC objects have great stability in the landfill, even in the case that part of the plasticizers migrate to the surface layers of flexible PVC, these would be bio-degrade by 90% in 30 days.

It must also be noted that the sealing of the bottom of certain landfills is ensured by plasticized PVC films.

However, the deposit of PVC in landfills can not be considered a solution. Recycling or thermal recovery are preferable.